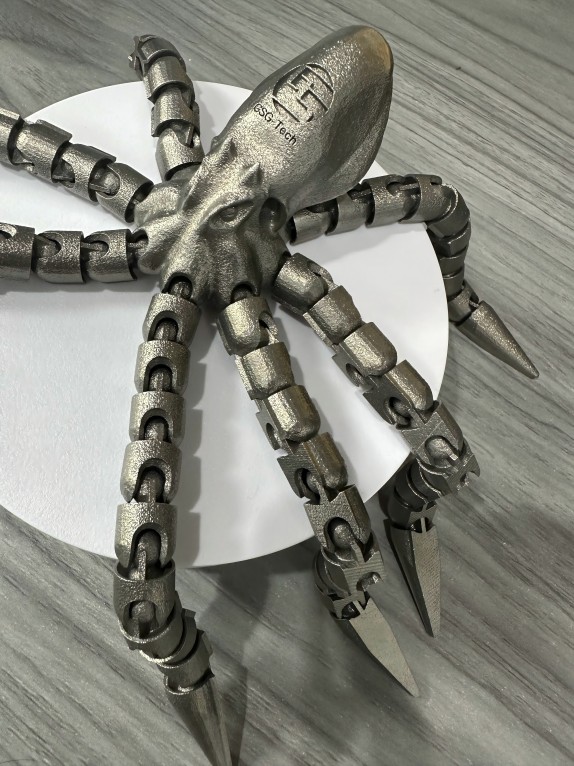

Nuper demonstrationem metalli fecimus.Impressio tridimensionalis, et id felicissime perfecimus, quid igitur est metallumImpressio tridimensionalisQuae sunt eius commoda et incommoda?

Impressio tridimensionalis metallica est technologia fabricationis additiva quae res tridimensionales construit addendo materias metallicas stratis post stratis. Hic est introductio accurata ad impressionem tridimensionalem metallicam:

Principium technicum

Sinterizatio laserica selectiva (SLS): Usus radiorum lasericorum altae energiae ad pulveres metallicos selective liquefaciendos et sinterizandos, materiam pulveris ad temperaturam paulo infra punctum liquefactionis calefaciendo, ita ut vincula metallurgica inter particulas pulveris formentur, ita objectum stratis stratis construendo. In processu impressionis, stratum uniforme pulveris metallici primum in suggestu impressionis ponitur, deinde radius laser pulverem secundum formam sectionis transversalis objecti perscrutatur, ita ut pulvis perscrutatus simul liquefiat et solidificetur. Post completionem strati impressionis, suggestus distantiam certam descendit, deinde novum stratum pulveris extenditur, processum supradictum itera donec totum objectum impressum sit.

Fusio Laser Selectiva (SLM): Similis SLS, sed cum energia laseris maiori, pulvis metallicus penitus liquefieri potest ad structuram densiorem formandam, densitas maior et proprietates mechanicae meliores obtineri possunt, et robur ac accuratio partium metallicarum impressarum partes per processum fabricationis traditionalem productas maiores sunt, prope vel etiam superant. Apta est ad partes fabricandas in industria aëronautica, apparatu medico, et aliis campis qui magnam praecisionem et efficaciam requirunt.

Liquefactio fasciculi electronici (EBM): Usus fasciculorum electronicorum ut fons energiae ad pulveres metallicos liquefaciendos. Fasciculus electronicus proprietates habet altae densitatis energiae et altae celeritatis perscrutationis, quae celeriter pulverem metallicum liquefacere et efficientiam impressionis augere possunt. Impressio in ambitu vacuo reactionem materiarum metallicarum cum oxygenio durante processu impressionis vitare potest, quod aptum est ad imprimendum mixturas titanii, mixturas niccoli fundatas, et alias materias metallicas sensibiles ad contentum oxygenii, saepe in industria aëronautica, apparatu medico, et aliis campis pretiosis adhibentur.

Extrusio materiae metallicae (ME): Methodus fabricationis innixa extrusioni materiae, per caput extrusionis materiam metallicam in forma serici vel pastae extrudit, simulque calefacit et curat, ut formatio accumulationis stratis perficiatur. Comparata cum technologia liquefactionis lasericae, sumptus collocationis minor, flexibilior et commodior est, praesertim apta ad progressionem initialem in ambitu officii et ambitu industriali.

Materiae communes

Mixtura titanii: commodis praedita est magnae firmitatis, densitatis humilis, bonae resistentiae corrosionis et biocompatibilitatis; late adhibetur in aëronauticis, apparatu medico, autocinetis aliisque campis, ut in alis machinarum aeroplanorum, articulis artificialibus, et aliis partibus in fabricatione.

Chalybs inoxidabilis: bonam resistentiam corrosionis, proprietates mechanicas et proprietates processus habet, pretium relative vile, una ex materiis vulgo adhibitis in impressione tridimensionali metallorum est, ad varias partes mechanicas, instrumenta, apparatum medicum et cetera fabricanda adhiberi potest.

Mixtura aluminii: densitatis humilis, firmitatis magnae, conductivitatis thermalis bonae, apta ad fabricationem partium quae pondus magnum requirunt, ut cylindri machinae autocineticae, partes structurales aerospatiales, et cetera.

Mixtura niccoli fundata: praestans firmitate temperaturae altae, resistentia corrosionis et resistentia oxidationis, saepe in fabricatione partium temperaturae altae, ut machinarum aeroplanorum et turbinarum gasi, adhibetur.

commodum

Gradus altus libertatis designandi: Facultas fabricationis formarum et structurarum complexarum, ut structurarum cancellatarum, structurarum topologice optimizatarum, etc., quae difficiles vel impossibilia sunt ad assequendum in processibus fabricationis traditis, spatium innovationis maius praebet designando productum, et partes leviores, altae efficaciae producere potest.

Numerum partium minue: partes plures in unum integrum integrari possunt, quo fit ut nexus et processus congregationis inter partes minuantur, efficientia productionis augeatur, sumptus minuantur, sed etiam firmitas et stabilitas producti augeatur.

Prototypatio rapida: Prototypum producti brevi tempore producere, cyclum evolutionis producti accelerare, sumptus investigationis et evolutionis minuere, et societatibus adiuvare potest ut producta celerius in forum inducant.

Productio ad usum accommodata: Secundum necessitates singulares clientium, producta singularia fabricari possunt ut requisitis specialibus variorum clientium satisfaciant, apta implantationibus medicis, gemmis, aliisque campis ad usum accommodatis.

Limitatio

Mala qualitas superficiei: Asperitas superficiei partium metallicarum impressarum relative alta est, et curationes posteriores, ut triturationem, polituram, saburrationem, etc., requiruntur ad superficiem meliorem reddendam, sumptum et tempus productionis augentes.

Vitia interna: vitia interna, ut pori, particulae non fusae, et fusio incompleta, in processu impressionis fieri possunt, quae proprietates mechanicas partium afficiunt, praesertim in applicatione oneris magni et oneris cyclici; necesse est incidentiam vitiorum internorum reducere per optimizationem parametrorum processus impressionis et adhibitionem methodorum post-processus idonearum.

Limitationes Materiarum: Quamquam genera materiarum metallicarum impressionis tridimensionalis praesto crescunt, adhuc quaedam limitationes materiarum exstant, comparatione cum modis fabricationis traditis, et quaedam materiae metallicae summae efficacitatis difficilius imprimuntur et sumptus altior est.

Quaestiones sumptuum: Sumptus instrumentorum et materiarum impressionis tridimensionalis metallicae relative altus est et celeritas impressionis tarda, quae non tam sumptuum efficax est quam processus fabricationis traditionales ad productionem magnae scalae, et nunc aptissima est ad productionem parvarum copiarum, productionem personalizatam et areas cum altis requisitis qualitatis et effectuum producti.

Complexitas technica: Impressio tridimensionalis metallica complexos parametros processus et moderationem processus implicat, quod operarios peritos et auxilium technicum requirit, et altum gradum technicum et experientiam operatorum requirit.

Campus applicationis

Aerospatialis: Ad fabricandas alas machinarum aeronauticarum, discos turbinarum, structuras alarum, partes satellitum, et cetera, adhibetur, quae pondus partium minuere, efficientiam cibusis augere, sumptus productionis reducere, et summam efficaciam ac firmitatem partium praestare possunt.

Autocinetum: Fabricare cylindrorum machinae autocineticae, involucrum transmissionis, partes structurales leves, etc., ad designationem levem autocinetorum assequendam, oeconomiam cibustibilis et efficaciam augendam.

Medica: Productio instrumentorum medicorum, articulationum artificialium, orthoseorum dentalium, instrumentorum medicorum implantabilium, etc., secundum differentias singulares aegrotorum, fabricatione ad mensuram aptata, aptitudinem instrumentorum medicorum et effectus curationis auget.

Fabricatio Formarum: Fabricatio formarum iniectarum, formarum fusarum, etc., cyclum fabricationis formarum abbreviat, sumptus minuit, accuratiam et complexitatem formae auget.

Electronica: Fabricatio radiatorum, testarum, tabularum circuituum instrumentorum electronicorum, etc., ad fabricationem integratam structurarum complexarum assequendam, efficaciam et dissipationem caloris instrumentorum electronicorum emendandam.

Ornamenta: Secundum ingenium designatoris et necessitates emptorum, varia ornamenta singularia fabricari possunt ad efficientiam productionis augendam et personalizationem producti.

Tempus publicationis: XXII Novembris MMXXIV