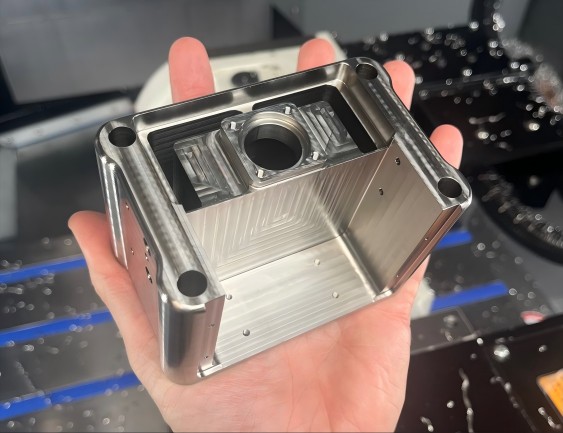

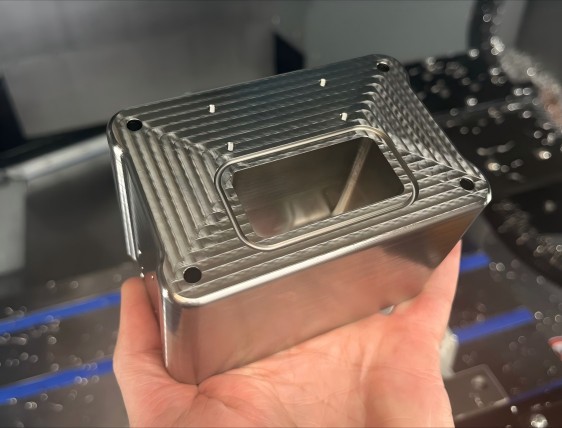

Nuper seriem partium ex chalybe inoxidabili fabricavimus. Exactitudo necessaria est altissima, ad ±0.2μm pervenire debet. Materia chalybis inoxidabilis satis dura est.Machinatio CNC materiarum chalybis inoxidabilis, mensurae correspondentes ex praeparatione ante processum, moderatione processus processus et post processum sumi possunt ad accuratiam processus augendam. Methodus specifica sequitur:

Praeparatio ante processum

• Instrumentum aptum elige: secundum proprietates materiarum chalybis inoxidabilis, ut puta duritiam magnam, tenacitatem, etc., instrumentum elige cum duritie magna, resistentia magna attritionis et resistentia bona adhaesionis, ut instrumenta carburi tungsteni cobalti vel instrumenta obducta.

• Optimiza consilium processus: vias processus accuratas et rationabiles forma, processus rudis, semi-poliendi et poliendi rationabiliter dispone, et marginem processus 0.5-1mm ad subsequentem processum altae praecisionis relinque.

• Materias brutas altae qualitatis para: Qualitatem aequalem materiarum brutarum et nulla vitia interna cura ut errores accuratae machinationis a materia ipsa causati minuantur.

Moderatio processus

• Parametros secandi optimiza: Parametros secandi idoneos per probationes et accumulationem experientiae determina. Generaliter, usus celeritatis secandi inferioris, modici progressus et parvae profunditatis secandi detritionem instrumenti et deformationem machinationis efficaciter minuere potest.

• Usus lubricationis refrigerantis idoneae: usus fluidorum secandi cum bonis proprietatibus refrigerantibus et lubricantibus, ut emulsio additiva pressionis extremae continente vel fluida secandi synthetica, temperaturam secandi reducere, frictionem inter instrumentum et opus minuere, productionem tumorum lamellarum inhibere potest, ita accuratiam processus augens.

• Optimizatio Itineris Instrumenti: Dum programmatur, iter instrumenti optimizatur, et modus ac trajectoria secandi rationabiles adoptantur ad vitandas conversiones acutas instrumenti et accelerationes et retardationes frequentes, fluctuationem vis secandi reducendam, et qualitatem ac accuratiam superficiei machinationis emendandam.

• Implementatio detectionis et compensationis interretialis: instructum systemate detectionis interretialis, monitorio in tempore reali errorum magnitudinis et formae materiae in processu processus, adaptatio opportuna situs instrumenti vel parametrorum processus secundum eventus detectionis, compensatio errorum.

post-processus

• Mensura accurata: Utere CMM, profilatore, aliisque instrumentis mensurae accuratae ad materiam post processum plene metiendam, ad accuratam magnitudinis et formae notitiam obtinendam, et ad fundamentum praebendum pro subsequenti analysi accurata et qualitatis inspectione.

• Analysis et correctio errorum: Secundum eventus mensurationum, causas errorum machinationis, ut detritionem instrumentorum, deformationem vis secandi, deformationem thermalem, etc., analysare et mensuras congruentes ad accommodandum et emendandum, ut instrumenta substituere, technologiam processus optimizare, parametros machinae accommodare, etc., capere.

Tempus publicationis: Decembris XX, anno MMXXIV